Giving an umbrella as a gift has many benefits.Gift umbrellas are given

February 3, 2023

Styles of advertising umbrellas

February 3, 2023

Giving an umbrella as a gift has many benefits.Gift umbrellas are given

February 3, 2023

Styles of advertising umbrellas

February 3, 2023

GreenSource

The production of umbrellas usually includes the following main steps:

Design and planning

Style design

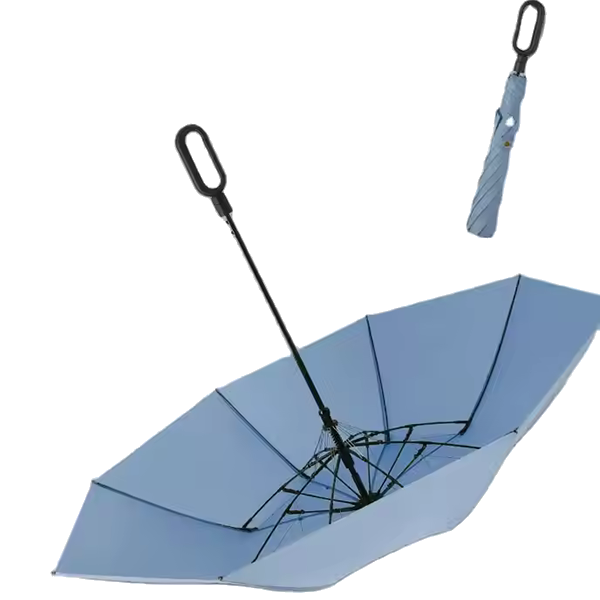

Designers design the appearance, shape, color and pattern of umbrellas according to market demand, popular trends and customer requirements. This includes determining the style of the umbrella surface, the structure of the ribs and the style of the handle.

For example, designing a fashionable folding umbrella may use bright colors and unique patterns to attract young consumers.

Material selection

Choose appropriate materials according to design requirements. The main materials include umbrella cloth, ribs, handles, springs, rivets, etc.

Umbrella cloth is usually made of nylon, polyester fiber and other materials, and needs to have waterproof, durable, UV resistance and other properties. Umbrella ribs can be steel, aluminum alloy, fiberglass, etc., to ensure strength and toughness. The handle is made of plastic, rubber, wood, etc. to provide a comfortable grip.

Cutting and sewing

Umbrella cloth cutting

Cut the selected umbrella cloth according to the design size. This usually requires the use of professional cutting equipment to ensure cutting accuracy and efficiency.

For example, for a circular umbrella, the umbrella cloth needs to be cut into a circle and leave appropriate edges for sewing

Umbrella sewing

The cut umbrella cloth is sewn to form a complete umbrella. During the sewing process, attention should be paid to the quality of the thread and the firmness of the stitching to ensure that the umbrella surface will not crack or derail during use.

For some high-end umbrellas, special sewing processes such as double-thread sewing or waterproof sewing may also be used to improve the quality of the umbrella.

Umbrella rib assembly

Umbrella rib processing

Umbrella rib materials (such as steel bars, aluminum alloy tubes, etc.) are cut, bent, punched, etc. to meet the shape and size required by the design.

For example, the steel bar is cut into a suitable length, then bent into the shape of the umbrella rib by a bending device, and holes are punched in appropriate positions for installing springs and rivets.

Umbrella rib assembly

The processed umbrella rib parts are assembled. This includes installing accessories such as springs, rivets, and umbrella beads so that the umbrella ribs can be opened and closed flexibly.

The function of the spring is to provide the force to open the umbrella, the rivet is used to connect the rib parts, and the umbrella bead can prevent the end of the rib from scratching the umbrella or the user.

Handle production and installation

Handle production

The handle is made according to the design requirements. The method of making the handle varies depending on the material. For example, plastic handles can be made by injection molding, and wooden handles can be carved and polished.

For some high-end umbrellas, the handle may also be inlaid with gemstones, metal decorations, etc. to increase its beauty and value.

Handle installation

The made handle is installed on the umbrella pole. This usually requires the use of screws, glue and other fixing methods to ensure that the handle is firmly installed and will not loosen or fall off.

5. Quality inspection and packaging

Quality inspection and packaging

Quality inspection

The produced umbrellas are fully inspected for quality. The inspection content includes the waterproof performance of the umbrella surface, the strength and stability of the ribs, the firmness of the handle, the smoothness of opening and closing, etc.

For example, the umbrella is tested in simulated rain to check whether there is any water leakage; the ribs are pressure tested to ensure that they can withstand a certain amount of wind force.

Packaging

The umbrellas that have passed the quality inspection are packaged. The packaging method can be selected according to customer requirements and product characteristics. Common packaging includes plastic bag packaging, paper box packaging, gift box packaging, etc.

Product information, brand logo, etc. are usually printed on the packaging to improve the recognition and aesthetics of the product.

In short, the production process of umbrellas requires careful production and strict testing in multiple links to ensure the quality and performance of the products. Umbrellas of different types and grades may vary in production steps and processes, but generally follow the above basic process.