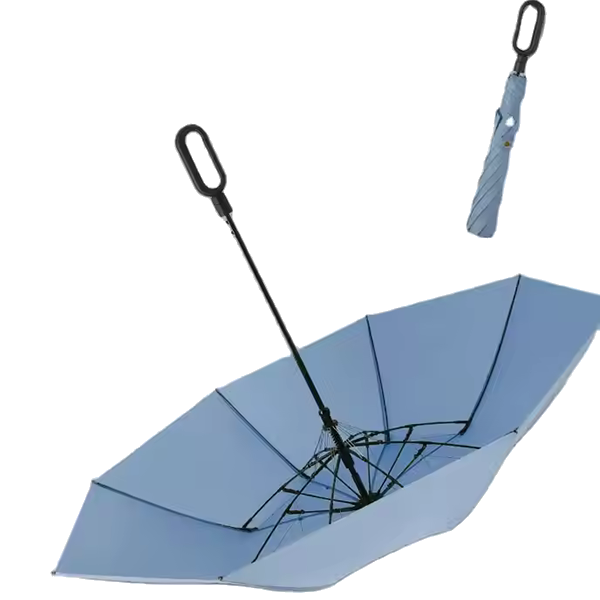

Straight Umbrella Introduction

February 3, 2023

Giving an umbrella as a gift has many benefits.Gift umbrellas are given

February 3, 2023

Straight Umbrella Introduction

February 3, 2023

Giving an umbrella as a gift has many benefits.Gift umbrellas are given

February 3, 2023umbrella sample production and proofreading confirmation

Key points

Color accuracy:

se professional color management tools and equipment, such as spectrophotometers, to measure and calibrate colors. During the printing process, ensure the color consistency of different batches of ink to ensure that the color of each sample meets the customer’s design requirements.

Considering that different umbrella materials may affect the presentation of colors, a small sample test is required before formal printing to observe the effect of the color on the actual umbrella material and confirm with the customer.

Pattern clarity and detail:

For complex pattern designs, ensure that the details of the pattern can be clearly presented during the printing process. When screen printing, pay attention to the mesh selection of the screen. The higher the mesh, the finer the pattern, but the printing difficulty will increase accordingly; for thermal transfer, ensure that the printer resolution is high enough.

Check whether the edges of the pattern are clear to avoid blurry or jagged edges. For patterns with gradient effects, ensure that the color transition is natural and smooth.

Printing position and alignment:

According to the customer’s design requirements, accurately determine the printing position of the pattern on the umbrella surface. Use positioning tools and markers to ensure that the pattern position of each umbrella surface is consistent during batch printing.

If there are multiple elements of the pattern on the umbrella surface (such as trademarks and text), it is necessary to ensure that the relative position between them is accurate and aligned.

GREENSOURCE

Steps and relevant points for printing umbrella samples according to customer designs:

Steps

Design file preparation:

Customers provide designed pattern files, usually vector graphics files (such as AI, EPS and other formats) to ensure printing clarity. These patterns may include trademarks, specific artistic patterns, text information, etc.

The designer will check the resolution, color mode (usually CMYK mode for printing) and integrity of the graphics to ensure that the design file meets the printing requirements.

Selection of printing method:

Screen printing:

Making screen: Make the corresponding screen according to the design pattern, and form the leaking part of the pattern on the screen through photosensitive glue.

Mix ink: Use special printing ink to mix according to the color required by the customer.

Printing operation: Open the umbrella surface and fix it on the printing equipment, and print the ink evenly on the umbrella surface through the screen. Print one color each time, and multiple overprints are required for multi-color patterns.

Heat transfer:

Print transfer paper: Print the design pattern on special transfer paper through a thermal transfer printer. The ink used can be firmly combined with the umbrella surface material at high temperature.

Transfer process: Cover the printed transfer paper on the umbrella surface, apply high temperature and pressure through the hot press, so that the pattern on the transfer paper is transferred to the umbrella surface.

Sample proofreading and adjustment:

After printing, carefully check the sample umbrella. Check the printing quality of the pattern, including whether the color is accurate, whether there is color difference, whether the pattern is clear, whether there is missing printing or ghosting, etc.

Make adjustments based on the proofreading results. If there is a color deviation, you can adjust the ink formula or the print settings of the thermal transfer; if there are pattern defects, you may need to remake the screen or adjust the parameters in the transfer process.